Unpacking ZEISS’s commitment to in-house production, from raw materials to final optical and industrial solutions, ensuring unparalleled quality.

Vertical integration is a strategic business approach where a company gains control over multiple stages of its supply chain, traditionally handled by external suppliers. In the context of ZEISS, a global technology leader in optics and optoelectronics, vertical integration is not merely a business strategy; it’s a fundamental pillar of its operational philosophy, deeply ingrained in its pursuit of precision, quality, and innovation.

Key Features of ZEISS’s Vertical Integration:

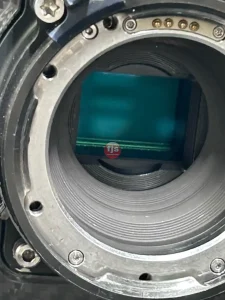

- In-House Manufacturing of Critical Components: ZEISS meticulously manufactures a significant portion of its critical components internally. This includes everything from specialized optical glass and crystal growth to complex mechanical parts and electronic assemblies. By controlling these processes, ZEISS ensures that every component meets its stringent quality standards.

- Proprietary Material Development: A cornerstone of ZEISS’s vertical integration is its commitment to developing and producing its own advanced materials. This extends to unique glass formulations with specific refractive indices, dispersion characteristics, and mechanical properties, essential for achieving the optical performance for which ZEISS is renowned.

- Advanced Coating Technologies: ZEISS has developed and implements proprietary coating processes that are crucial for optimizing light transmission, reducing reflections, and enhancing durability in its lenses and optical systems. These complex multi-layer coatings are applied in-house, offering unparalleled control over performance and longevity.

- Integrated Software and Hardware Development: Beyond physical components, ZEISS also integrates its software development with its hardware engineering. This ensures seamless interaction and optimized performance across its diverse product portfolio, from microscopy and medical technology to industrial metrology and lithography optics.

- Quality Assurance and Metrology Expertise: The very nature of vertical integration at ZEISS allows for continuous quality assurance at every stage of production. Leveraging its own world-leading metrology solutions, ZEISS can precisely measure and verify the quality of components and assemblies, minimizing defects and maximizing product reliability.

Benefits of ZEISS’s Vertical Integration:

- Uncompromising Quality Control: By owning the entire process, ZEISS maintains an unparalleled level of control over the quality of its products. This eliminates reliance on external suppliers whose quality standards might not align with ZEISS’s exacting requirements.

- Enhanced Innovation and R&D: Vertical integration fosters a unique environment for innovation. Direct control over materials and manufacturing processes allows ZEISS engineers and researchers to experiment with new designs, materials, and technologies more effectively, accelerating the development of groundbreaking solutions.

- Supply Chain Resilience: In an increasingly volatile global economy, controlling key aspects of the supply chain provides significant resilience against disruptions. ZEISS is less susceptible to external supply shortages or quality issues that could impact production.

- Protection of Intellectual Property: In-house production of specialized components and materials helps safeguard ZEISS’s valuable intellectual property, preventing sensitive technologies from falling into competitors’ hands.

- Optimized Performance and System Integration: When a company designs and manufactures its components from the ground up, it can achieve superior system integration and optimized overall performance, leading to products that are more reliable and efficient.

- Cost Efficiency in the Long Run: While initial investments in vertical integration can be substantial, it often leads to long-term cost efficiencies by reducing procurement costs, minimizing waste, and streamlining production processes.`

Conclusion:

ZEISS’s commitment to vertical integration underscores its dedication to engineering excellence and its relentless pursuit of precision. By maintaining extensive control over its design and manufacturing processes, from the foundational materials to the final product, ZEISS not only ensures the superior quality and performance of its optical and optoelectronic solutions but also solidifies its position as a pioneer in technological innovation. This strategy is critical to delivering the high-performance products that its diverse global customer base has come to expect, whether in research, industry, or healthcare.

Questions and Answers:

- Q: Why is vertical integration particularly important for a company like ZEISS?

- A: For ZEISS, dealing with highly precise optical and optoelectronic components, vertical integration is crucial for maintaining an extremely high level of quality control, enabling proprietary material development, protecting intellectual property, and fostering innovation that would be difficult to achieve relying solely on external suppliers.

- Q: Does vertical integration always mean ZEISS produces everything itself?

- A: While ZEISS produces a significant portion of its critical components and materials in-house, vertical integration doesn’t necessarily mean 100% self-sufficiency for every single part. It implies strategic control over the most vital and differentiating aspects of its production process to ensure quality, performance, and innovation.

- Q: How does vertical integration benefit customers of ZEISS products?

- A: Customers benefit from higher product quality, enhanced reliability, cutting-edge innovation, and superior performance. ZEISS’s ability to control its entire process translates directly into more precise, durable, and effective instruments and solutions for its users.

- Q: What are the potential challenges of a highly vertically integrated model?

- A: Challenges can include significant capital investment in manufacturing facilities and R&D, potential for reduced flexibility if market demands shift rapidly, and the need for extensive in-house expertise across various disciplines. However, for ZEISS, the benefits largely outweigh these challenges due to the specialized nature of its products.